Panels are pressed to the vessels deck by being enclosed in a sealed bag, attaching a vacuum pump and letting atmospheric pressure do the work of pressing the panels to the substrate. This ensures a perfect bond without air entrapment. Pressure of up to 10 tons/m ² can be applied.

If a sub-deck is needed, we can offer lightweight and waterproof PVC Foam to keep weight down and improve thermal insulation. Alternatively, our cork & rubber underlay is environmentally friendly, FSC certified and offers excellent thermal and sound insulation.

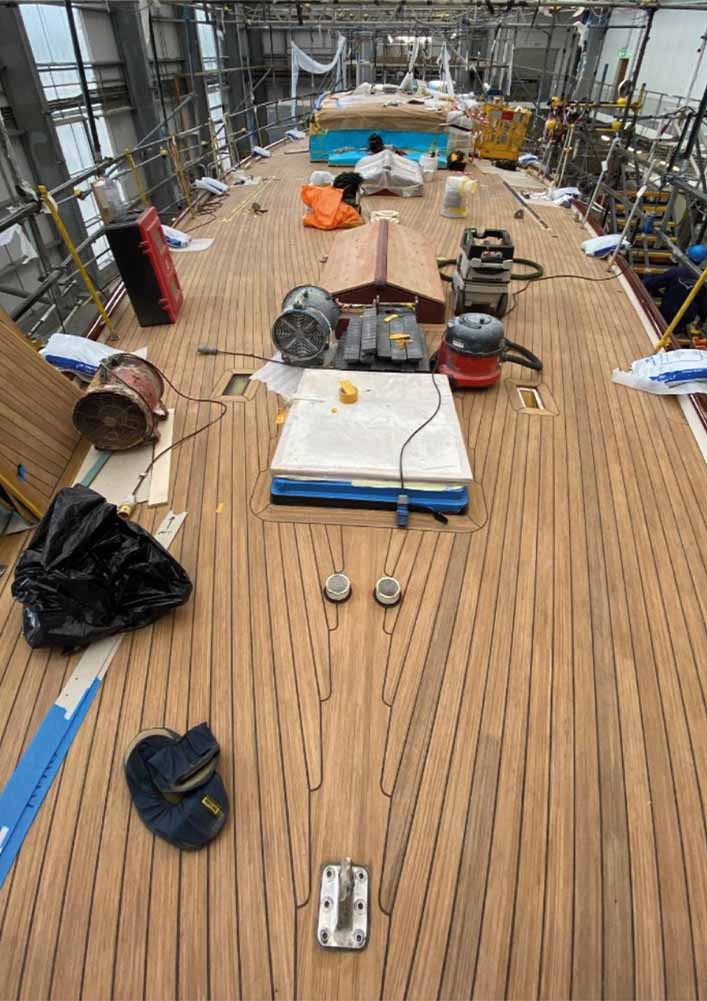

After final sanding, deck hardware can be re-mounted, caulk beadings applied and then it’s time to launch!